Comprehensive Protection: The Ultimate Guide to Bunding Solutions

Preventing chemical spills is crucial for keeping your workplace safe and staying on the right side of environmental regulations. That’s where bunding comes in—it’s a protective barrier designed to contain spills and prevent them from spreading. Learn everything you need to know about choosing and implementing the right bunding solutions to meet your business’s specific needs.

Understanding Bunding and Its Importance

What Is Bunding?

Bunding is a containment barrier designed to prevent liquid spills from spreading beyond their designated area. It’s like a safety net for your workplace, ensuring that any accidental leaks or spills stay contained and manageable. By keeping spills in check, bunding helps protect both your facility and the surrounding environment from potential harm.

Why Is Bunding Necessary?

Bunding is necessary for several reasons—first and foremost, it’s about keeping people safe and minimising the risk of accidents. Legally, businesses handling hazardous liquids are required to have bunding systems in place to comply with environmental and safety regulations. Beyond legal obligations, bunding plays a critical role in protecting the environment by preventing harmful substances from contaminating soil and water sources.

Types of Bunding Solutions

When it comes to bunding, one size doesn’t fit all. Take a look at the different types of bunding solutions available and how they can meet various business needs:

Concrete Bunds

Concrete bunds are a go-to choice for permanent installations where durability and long-term protection are needed. They’re designed to withstand heavy use and harsh conditions, making them ideal for facilities with significant spill risks. Once in place, concrete bunds provide a robust, reliable barrier built to last.

Collapsible Bunds

Collapsible bunds are perfect for situations where flexibility and quick deployment are essential. They can be easily set up and taken down, making them ideal for temporary or mobile applications like construction sites or emergency response. With collapsible bunds, you get protection that moves with you, wherever you need it.

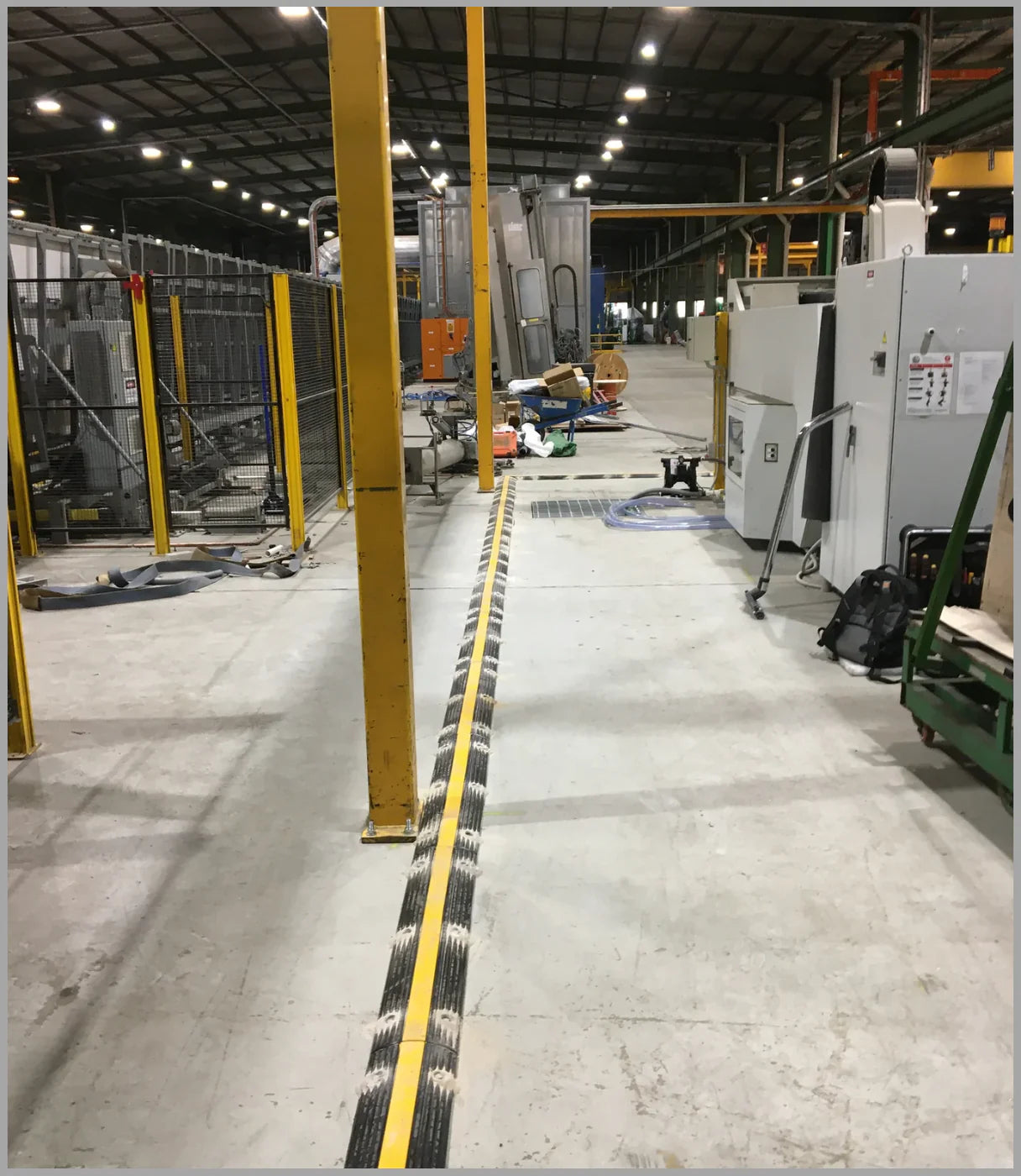

Bunding Blocks

Bunding blocks offer a modular approach to spill containment, allowing you to create customised bunding areas to fit your specific needs. They’re easy to assemble and can be configured in various shapes and sizes, providing versatility in spill management. Whether you’re dealing with small spaces or large areas, bunding blocks give you the flexibility to build the containment solution that works best for you.

Spill Pallets

Spill pallets are designed to contain spills from drums, containers, and other liquid storage units, offering a simple yet effective solution for managing leaks. They’re a must-have for any facility that handles hazardous liquids in portable containers, helping to catch spills before they become a bigger problem. With spill pallets, you can keep your storage areas safe and compliant with minimal hassle.

Selecting the Right Bunding Solution

Choosing the right bunding solution is crucial for ensuring safety, compliance, and efficiency in your facility. Here’s how to make the best choice for your specific needs:

Assessment of Needs

Before selecting a bunding solution, assess your facility’s specific requirements:

- Identify the types of chemicals you’re handling—different substances may require different containment measures.

- Estimate the volume of liquids that could potentially spill to determine the capacity needed for effective bunding.

- Consider your facility layout, including available space and access points, to ensure the bunding solution fits seamlessly into your operations.

Material Considerations

When selecting a bunding solution, the material is key to ensuring long-term effectiveness. Choose materials compatible with the chemicals you store, as certain substances can degrade or weaken the bunding over time. Matching the bunding material to the stored chemicals prevents leaks and maintains a strong, reliable barrier.

Regulatory Compliance

In Australia, bunding solutions must meet regulatory standards to ensure environmental and workplace safety. These regulations dictate everything from the bunding’s capacity to its construction materials, depending on the chemicals and quantities involved. Following the regulatory compliance for bunding not only protects your business from fines and legal issues but also ensures the safety of your workers and the environment.

Installation and Maintenance of Bunding Systems

Proper installation and ongoing maintenance are key to getting the most out of your bunding systems. Here’s what you need to know to keep your bunds in top shape:

Installation Tips

To ensure a successful installation, keep these practical tips in mind:

- Prepare the site: Clear the area of debris and ensure the surface is level before installation.

- Follow manufacturer guidelines: Each type of bund has specific installation instructions—stick to them for best results.

- Seal connections: For modular bunds, make sure all joints and connections are properly sealed to prevent leaks.

- Check alignment: Ensure that bunds are correctly aligned to avoid gaps or weak points in the containment area.

Maintenance Best Practices

Regular maintenance is essential for long-term effectiveness. Here are some bund maintenance best practices:

- Conduct routine inspections: Regularly check bunds for signs of wear, damage, or degradation.

- Clean as needed: Keep the bunding area free of debris and buildup that could compromise effectiveness.

- Repair promptly: Address any cracks, leaks, or damage immediately to prevent small issues from becoming big problems.

- Keep records: Document all maintenance activities to stay on top of compliance and ensure accountability.

Inspection and Testing

Regular inspection and testing ensure your bunding systems are functioning as intended. Depending on the type of bund and the substances it contains, inspections should be conducted at least quarterly, with more frequent checks for high-risk areas. Testing may involve water tests to check for leaks or structural assessments to ensure the bund remains secure. Consistent inspections and testing help catch issues early, keeping your bunding systems effective and compliant.

Real-World Applications

Bunding solutions aren’t just theoretical—they’re making a real difference in businesses around the world. Look at how bunding is being successfully implemented and solving tough challenges:

- Successful Implementation

Many industries have embraced bunding solutions to enhance safety and compliance. For instance, chemical plants use concrete bunds to protect against spills and environmental contamination, ensuring operations stay within legal guidelines. Logistics companies also rely on spill pallets to safely store and transport hazardous materials, reducing the risk of accidents during transit.

- Problem-Solving

Bunding solutions are also key to overcoming specific challenges in different environments. Construction sites often face the problem of temporary chemical storage, which is effectively managed with collapsible bunds that can be quickly deployed and removed. In the oil and gas sector, bunding blocks are used to create customised containment areas that adapt to the unique layout of each facility, providing tailored protection where it’s needed most.

Future Trends in Bunding Technology

The world of bunding is evolving, with new technologies and materials paving the way for even better protection. See what’s on the horizon for bunding solutions:

Innovations

Bunding technology is set to see significant advancements in materials and design. Future bunds may incorporate smart materials that can detect and respond to spills automatically, offering an extra layer of protection. Modular designs are also becoming more sophisticated, allowing for easier customisation and quicker installation, making bunding solutions more adaptable to any environment.

Sustainability Considerations

As industries move towards greener practices, eco-friendly bunding solutions are gaining traction. Industries are seeing a rise in bunds made from recycled or sustainable materials that still offer robust protection against spills. Companies are also adopting practices that reduce the environmental impact of bunding installations, such as using low-energy manufacturing processes and implementing systems that minimise waste.

Takeaway

Choosing and maintaining the right bunding solutions are essential for safeguarding your business and the environment from the dangers of chemical spills. Take proactive measures and follow best practices in bunding to prevent costly accidents and ensure compliance with safety regulations. By investing in quality bunding, you’re not just protecting your operations—you’re contributing to a safer, more sustainable future. For top-notch bunding solutions that you can trust, turn to BestBunding and secure the protection your business needs.

F.A.Q.

Need to choose the right bunding for your business? Here are answers to some frequently asked questions to guide you:

How do I know which type of bunding is right for my business?

Start by assessing the types of chemicals you handle and the specific risks in your facility. Consider factors like the volume of liquids, the environment, and the space available. Matching these needs with the right bunding solution ensures effective protection.

What are the legal requirements for bunding in my region?

Legal requirements for bunding vary by region, focusing on safety and environmental compliance. Check local regulations that specify bunding capacity, materials, and maintenance standards. Staying compliant not only protects your business but also avoids potential fines and legal issues.

Can bunding solutions be customised to fit unique facility layouts?

Yes, bunding solutions can be tailored to meet the specific needs of your facility. Custom bunding options allow you to design containment systems that fit your space and operational requirements perfectly. This ensures maximum efficiency and protection in any environment.

What are the common maintenance issues with bunding?

Common maintenance issues include wear and tear, leaks, and degradation of materials over time. Regular inspections and prompt repairs are key to addressing these issues and keeping your bunding system effective. Proper maintenance extends the life of your bunding and ensures continued compliance.