Which Floor Bund should you choose?

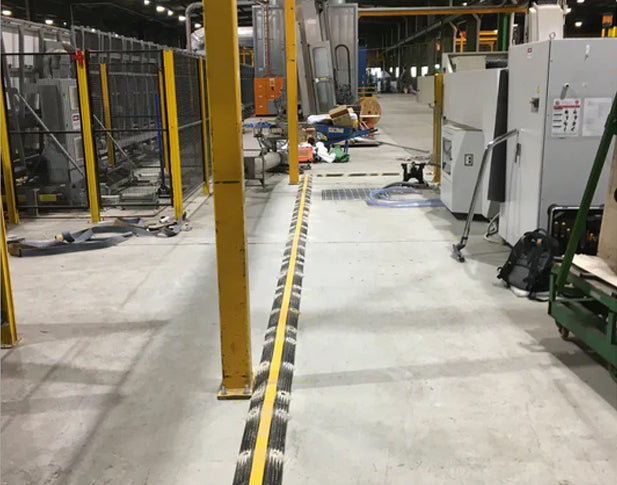

Choosing the right floor bunding is essential for creating a safe, compliant, and efficient workspace. Floor bunding is designed to prevent spills from spreading across floors, protecting your employees, equipment, and the environment from hazardous leaks. Depending on the type of traffic, the nature of stored chemicals, and the physical environment, different materials offer specific benefits to help you maintain a safe, spill-contained area. Here’s a guide to help you select the best floor bunding solution for your facility:

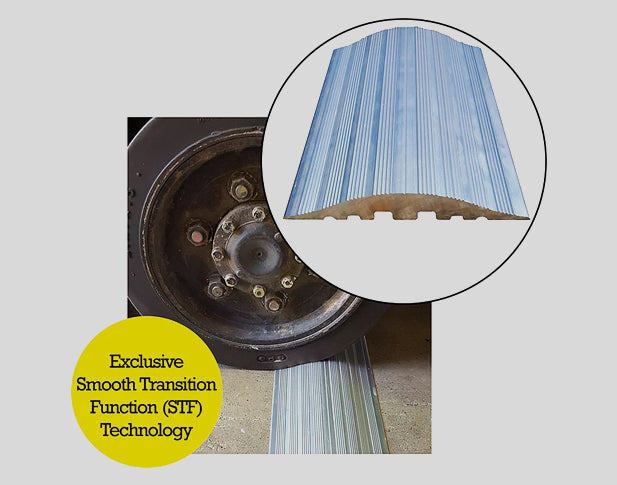

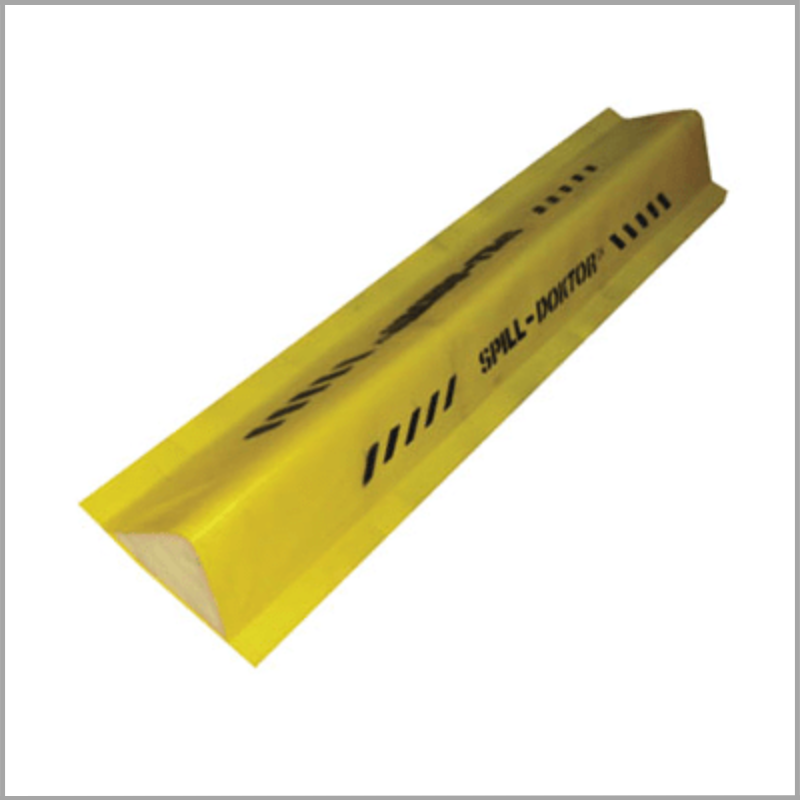

Each type of bunding has unique strengths that suit various industrial needs—from flexible, economical PVC bunding ideal for workshops, to heavy-duty urethane bunding for chemical facilities handling harsh substances. Below, we’ll outline the benefits of each to help you make an informed choice based on your specific requirements.